When designing objects of energy sources and heating networks, RUE "BELNIPIENERGOPROM" uses innovative technologies to create full-fledged BIM models of objects.

BIM process is a modern approach to design that provides transparency of project implementation, improves communication with customers, contractors and other project participants, organizes teamwork at a higher level with change tracking, which reduces the number of requests for changes to project documentation from builders, remove financial costs and save time.

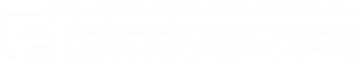

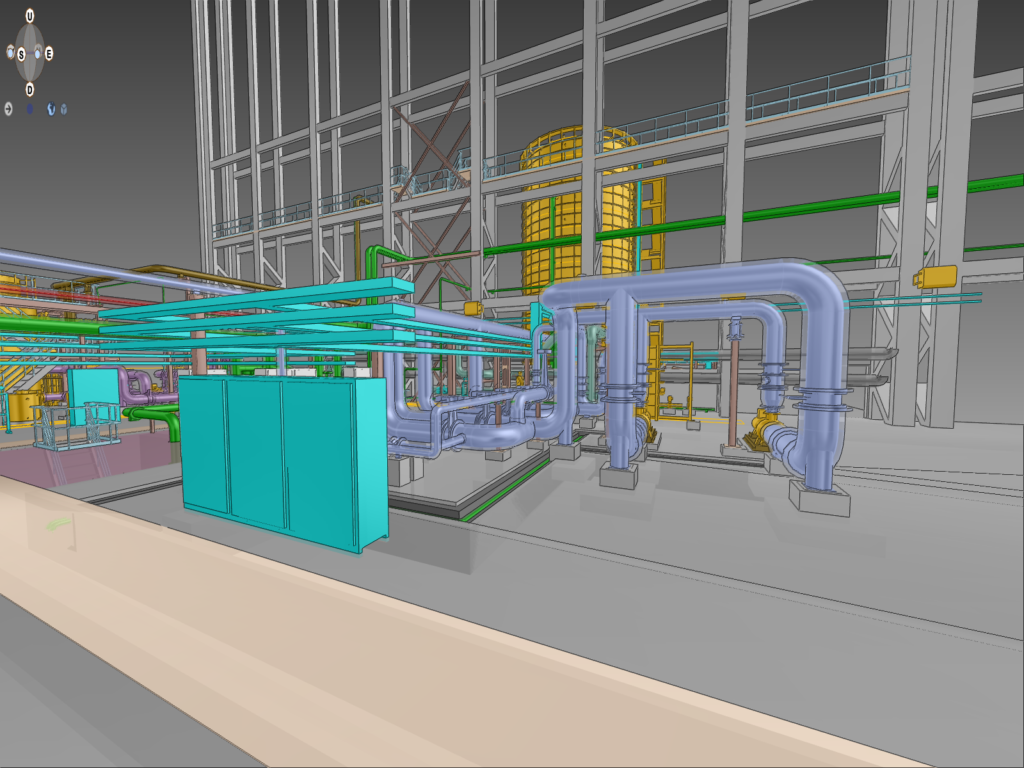

To achieve the result, the enterprise uses extensive software, more than 55 design and calculation programs, the main of which are Aveva E3D, Autodesk Revit, Tekla Structures. Aveva E3D, Autodesk Revit, Tekla Structures.

For effective internal interaction and coordination of work between all project participants, a common data environment (CDE) has been created. Departments and specialties have access to this repository and this is a single source of reliable and consistent information for all project participants. This allows to work with models of various disciplines in real time, quickly and efficiently make changes to design decisions, tracing the result in all interconnected models and provides a much more flexible form of project execution.

Thus, the model is a kind of database that contains all the graphic, geometric and alphanumeric parameters and codes related to the project or building. All innovations, changes and further developments are integrated into this model. Graphical changes also automatically change the BIM database by linking, adding, and configuring information in the form of properties and attributes to the component parts of the model.

The overall quality of the project is improved. The most common mistakes are collisions between building structures and its engineering networks, lack of technological openings for engineering systems, incorrect calculation of the volume of materials, caused primarily by unproductive interaction between specialists involved in the design of various sections, when working with BIM, they are immediately visible thanks to 3D models, and special tools that check for intersections and logistical inconsistencies, reducing the amount of rework in the last stages of design. Navisworks software provides the ability to jointly manage data from models of different disciplines, work in a single Navisworks model assembled on their basis, coordinate their actions and carry out the approval process, automatically find design errors and collisions, virtually study the object, simulate the construction process to search for collisions in time . The BIM model allows you to track the state of the facility at the stage of operation, including the control of the state of structures, engineering systems and equipment, if necessary, technical re-equipment, redevelopment, overhaul and reconstruction.

3D scanning

In order to introduce advanced design methods and modernize survey work, RUE Belnipienergoprom uses a special 3D scanner Faro Focus S150.

This is the cutting edge equipment in the design world. Laser scanning and 3D technology make it possible to obtain volumetric data of an existing object, and the results of laser scanning can be used to optimize the expansion of production, to simulate the installation of new or reconstruction of an old equipment in a limited workshop space, to carry out an inventory and even certification of equipment. The result of terrestrial laser scanning is a point cloud. Points can subsequently be integrated into special software systems, which ultimately produce a three-dimensional image. The results of the 3D scanner are used by the customer’s services and are used as initial or archival data when carrying out reconstruction, modernization, construction, technical re-equipment and operation of existing enterprises.